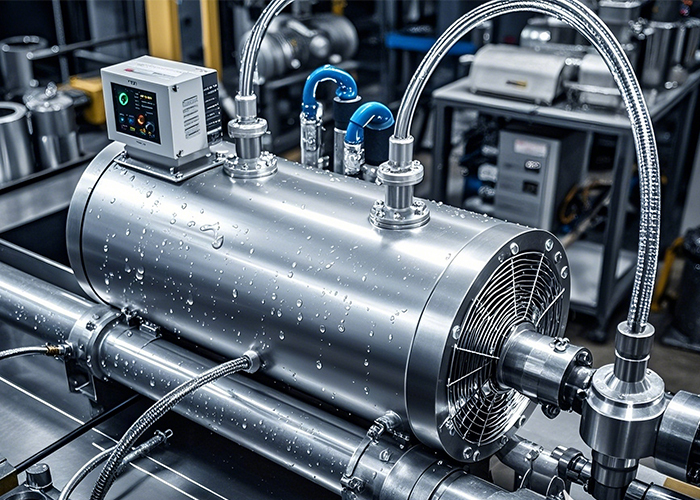

A metal finishing chiller is an industrial cooling system engineered to dissipate heat generated during metalworking processes such as cutting, grinding, welding, and electroplating. By maintaining a consistent and optimal temperature, these chillers prevent overheating, ensuring both the quality of the metal finish and the longevity of the equipment.

During metal finishing operations, significant heat is produced, which can adversely affect the material properties and precision of the workpiece. Excessive heat can lead to thermal expansion, warping, or undesirable metallurgical changes. Implementing a chiller system effectively manages this heat, preserving the integrity of the metal and ensuring consistent quality in the finishing process.

Metal finishing chillers operate by circulating a coolant—typically water or a water-glycol mixture—through the equipment. This coolant absorbs the heat generated during operations and transfers it away from the machinery, maintaining a stable temperature. Precise temperature control is crucial, as even minor fluctuations can impact the quality of the metal finish.

Processes: Engine part grinding, gear heat treatment, electroplating (e.g., chrome plating), laser cutting/welding.

Scenarios Requiring Chillers:

- Electroplating: Maintaining a constant electrolyte temperature to ensure uniform coating.

- Laser Processing: Cooling laser sources to prevent overheating and power fluctuations.

- Heat Treatment (e.g., Quenching): Controlling cooling rates to optimize material properties.

- Role of Chillers: Stabilizing process temperatures, preventing equipment overheating, and improving product consistency.

Processes: Precision machining of titanium/high-temperature alloys, electrolytic polishing, vacuum brazing.

Scenarios Requiring Chillers:

- Electrolytic Polishing: Controlling electrolyte temperature to maintain surface finish.

- Vacuum Brazing: Cooling heat exchangers in vacuum furnaces to ensure process stability.

- Role of Chillers: Ensuring high-precision machining, reducing thermal deformation, and extending equipment lifespan.

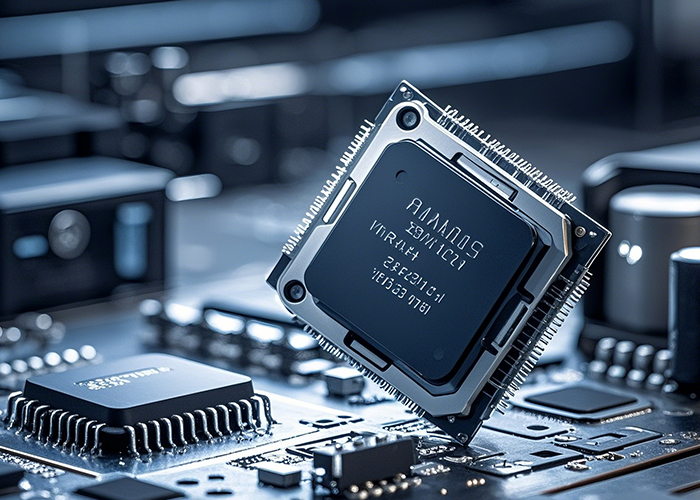

Processes: Chip lead frame plating, semiconductor etching, metal sputtering deposition.

Scenarios Requiring Chillers:

- Plating and Etching: Preventing temperature fluctuations in chemical solutions that affect micron-level precision.

- Laser Processing: Cooling laser sources to prevent overheating and power fluctuations.

- Sputtering Equipment: Cooling targets and chambers to maintain a stable vacuum environment.

- Role of Chillers: Avoiding thermal stress damage and ensuring process repeatability.

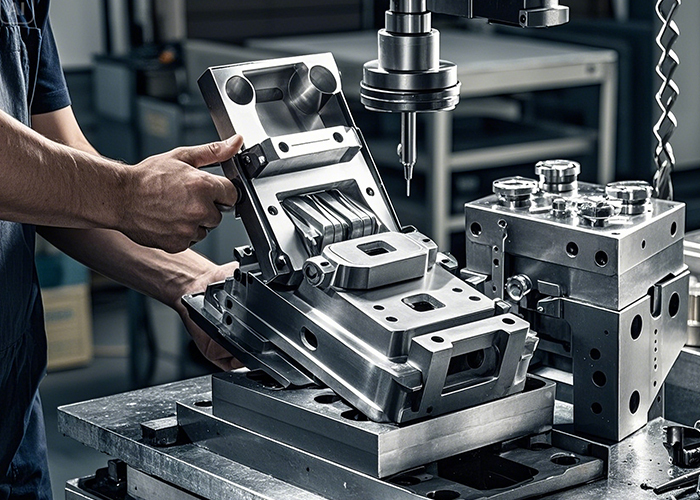

Processes: EDM (Electrical Discharge Machining), CNC precision milling, surface nitriding.

Scenarios Requiring Chillers:

- EDM: Cooling electrodes and working fluid to improve discharge accuracy.

- CNC Machining: Preventing spindle overheating that leads to deformation errors.

- Role of Chillers: Reducing thermal errors and improving mold dimensional accuracy.

Processes: Polishing of surgical instruments, surface treatment of implants (e.g., anodizing).

Scenarios Requiring Chillers:

- Anodizing: Controlling electrolyte bath temperature to avoid coating defects.

- Role of Chillers: Ensuring biocompatible surface quality.

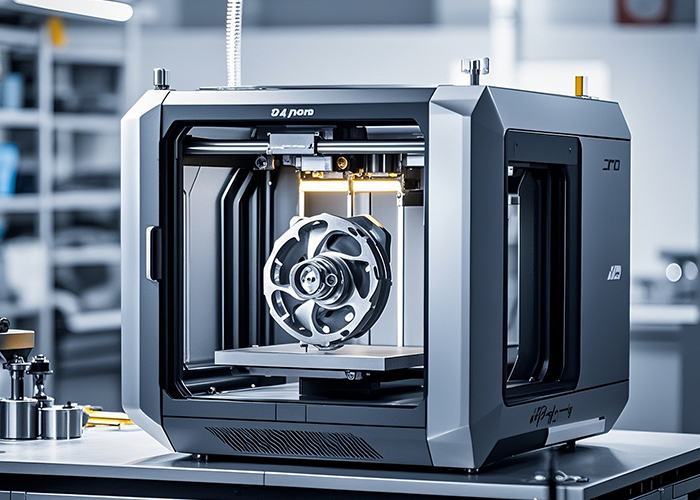

Processes: Selective Laser Melting (SLM), Electron Beam Melting (EBM).

Scenarios Requiring Chillers:

- Laser/Electron Beam Source Cooling: Maintaining energy source stability.

- Print Chamber Temperature Control: Preventing thermal stress-induced part cracking.

- Role of Chillers: Ensuring thermal management during printing and improving yield rates.

Ensure the chiller can handle the maximum heat load of your operations.

Look for chillers that offer precise temperature control to meet process requirements.

The chiller should be compatible with your existing equipment and processes.

Opt for models that offer efficient operation to reduce operational costs.

Consider the ease of maintenance and availability of support services.